Neofit®+Plus Expandable Pressure Pipe (EPP)

For fast, non-invasive replacement of lead house connections and leaking water pipes.

About Neofit

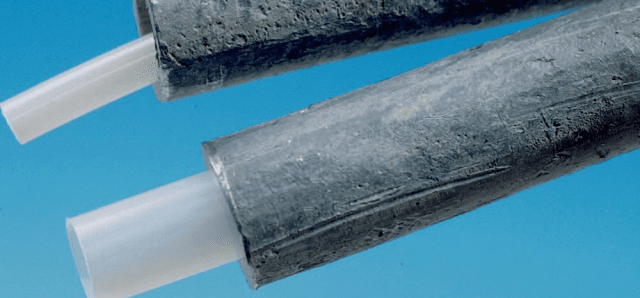

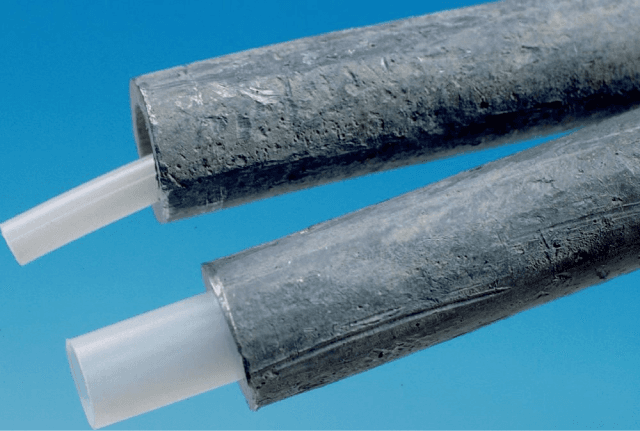

Neofit®+Plus is a non-invasive, advanced pipe technology for the repair of underground water services with inside diameters of 1/2" to 2".

Made of Virgin PET (Polyethylene Terephthalate), this innovative pipeline rehabilitation solution helps maintain the existing service pipe by creating a barrier inside and avoiding unnecessary replacement and extended disruption.

Offering a trenchless, minimally disruptive and environmentally friendly way to protect essential water pipelines, Neofit®+Plus has been used successfully across Europe since 1995.

Neofit®+Plus is particularly effective in cases of lead pipe rehabilitation and the maintenance of consumer supply pipes due to the barrier it forms between the pipeline and potable water.

The product is durable and stays resistant to leaching, with structural material that has been scientifically evaluated for longevity of 100+ years. When tested in line with the American Water Work Association's field guide for the hydrostatic testing of water service lines, results showed 0% lead in the water post installation.

Neofit®+Plus is part of Sanivar UK's range of trenchless rehabilitation solutions.

Demo

Watch how Neofit®+Plus is easily installed beneath infrastructure with minimal disruption.

Why Neofit®+Plus?

Neofit®+Plus is a minimally invasive, long-lasting solution for pipe rehabilitation and repair and can be installed in steel, copper, plastic and lead pipes in lengths up to 300ft. The smooth bore and thin-wall pipe of Neofit®+Plus provides the same or increased flow capacity and often only a single small access pit is required for installation.

Lead pipe refurbishment

Neofit®+Plus is a reliable solution for Lead Replacement Programmes, forming a continuous barrier between existing pipes and potable water. The presence of lead in drinking water can pose a significant threat to consumers which is where the trenchless and minimally invasive solution can provide significant support in preserving the flow of safe, clean water.

Customer supply pipes

The Neofit®+Plus solution is also strongly supported in the repair and maintenance of consumer supply pipes, by helping to prevent leakage and protect the supply of potable water. The pipe is made from a lightweight, strong plastic, widely used for food and beverage packaging, along with medical and pharmaceutical applications as it does not contain bisphenol-A (BPA) or phthalates (plasticisers). It is made from a stable, inert material that does not react with food or beverages, is resistant to attack by micro-organisms and will not biologically degrade.

Versatile use

Suitable for steel, copper, plastic, and lead pipes, with lengths available up to 300ft, it ensures safety and efficiency.

Versatile use

Suitable for steel, copper, plastic, and lead pipes, with lengths available up to 300ft, it ensures safety and efficiency.

Improved flow

The smooth bore and thin-wall design helps to maintain and even improve flow capacity.

Improved flow

The smooth bore and thin-wall design helps to maintain and even improve flow capacity.

Minimally disruptive

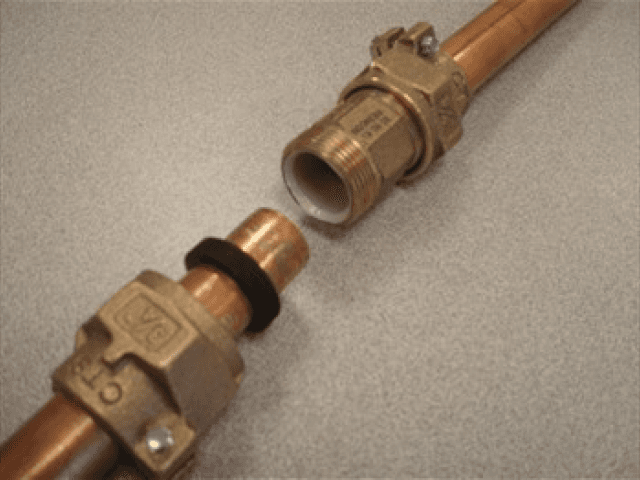

Neofit®+Plus typically only requires a single small access pit, minimising the need for excessive and disruptive works and can be connected to existing infrastructure including internal or external stop taps.

Minimally disruptive

Neofit®+Plus typically only requires a single small access pit, minimising the need for excessive and disruptive works and can be connected to existing infrastructure including internal or external stop taps.

Rapid installation

With the rapid Neofit®+Plus installation process, multiple installations can be completed in a day, allowing for return to service in as little as two to three hours.

Rapid installation

With the rapid Neofit®+Plus installation process, multiple installations can be completed in a day, allowing for return to service in as little as two to three hours.

Cost efficient

Neofit®+Plus can also provide significant cost savings of up to 85% when used in place of traditional dig-and-replace methods.

Cost efficient

Neofit®+Plus can also provide significant cost savings of up to 85% when used in place of traditional dig-and-replace methods.

Case Studies

Prior to being introduced to the UK, Neofit®+Plus has been widely used across Europe for many years.

200,000+

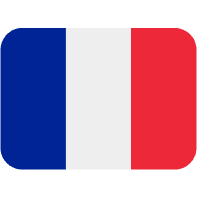

France

Neofit®+Plus in France

France alone has over 200,000 lead water services supported by Neofit®+Plus, exceeding 2,000 miles of pipe.

| City | # of Services | Installer |

|---|---|---|

| Monbéliard | 450 | Generale des Eaux |

| Dole | 200 | SNCTP |

| Orléans/Chateaudun | 300 | SAUR |

| LaTour du Pin | 300 | Fournier TP |

| Vichy | 200 | CBSE |

| Cahors | 300 | Capraro & Dubreuilh |

| Chalons-in-Champagne | 100 | Nord Est TP |

| Lons-le-Saunier | 100 | Service des Eaux |

| Pontarlier | 200 | Sté Toubin |

Since 2004

Germany

Since 1995

Netherlands/Belgium

Neofit®+Plus in France

France alone has over 200,000 lead water services supported by Neofit®+Plus, exceeding 2,000 miles of pipe.

| City | # of Services | Installer |

|---|---|---|

| Monbéliard | 450 | Generale des Eaux |

| Dole | 200 | SNCTP |

| Orléans/Chateaudun | 300 | SAUR |

| LaTour du Pin | 300 | Fournier TP |

| Vichy | 200 | CBSE |

| Cahors | 300 | Capraro & Dubreuilh |

| Chalons-in-Champagne | 100 | Nord Est TP |

| Lons-le-Saunier | 100 | Service des Eaux |

| Pontarlier | 200 | Sté Toubin |

Installation

The Neofit®+Plus System is a trusted solution for minimal disruption during installation, making it particularly suitable for pipelines running alongside other infrastructure such as under road crossings, in congested ground with other utilities and under residential dwellings.

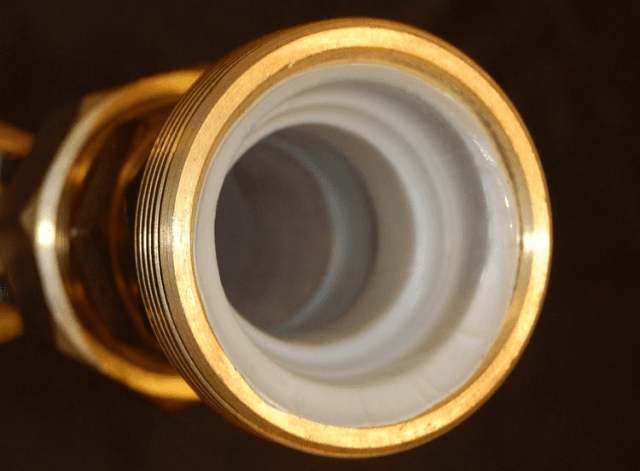

Neofit®+Plus can effectively rehabilitate old deteriorating pipes and lines with leaching contaminants, such as lead and copper pipe, acting as a barrier to protect potable water.

1

Preparation

Preparation

The water is shut off and the pipe is disconnected at the water main and the water meter or other convenient connection point within the house.

2

Cleaning

Cleaning

Air is blown through the lead pipe to remove the remaining water and the sediments which may be present in the lead pipe. Lead pipes do in general not develop hard encrustation, so in most cases mechanical cleaning is not needed, other than using a brush when there is some sediment at the inside which cannot be blown away. A small pig can also be blown through with compressed air or with a draw cord.

3

Insertion

Insertion

In this step, the small diameter NEOFIT liner is pushed or pulled into the host pipe. To this end it might be necessary to have a line inside to the host pipe to be able to pull the liner through the host pipe. This line can be inserted when blowing air through the pipe. The fact that the NEOFIT liner is rather flexible before it is expanded helps it navigate around bends etc.

4

Expansion

Expansion

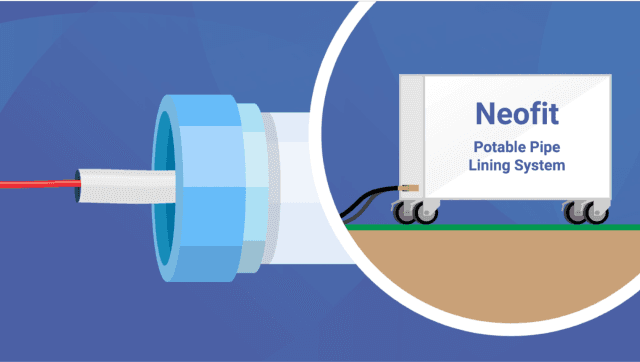

After the liner is inserted into the host pipe, the liner is connected to the circulation hoses and via the pressure unit, which regulates the heating of the liner by flushing hot water though and will automatically expand the pipe and cool it down afterwards.

5

Reconnecting

Reconnecting

Then finally the lined host pipe can be reconnected to the water meter or other connection point in the house and to the water main, with Neofit fittings that attach to standard plumbing fittings. Reconnection is done in such a way that no water is in contact with the lead pipe and cannot penetrate between the liner and host pipe. In practice this process is quick, mainly automated and does not require a lot of preparation and time to complete. Depending on the layout at the site, the length of the host pipe etc, the whole process typically takes between 1 and 3 hours. In general the time that the customer is disconnected from the water main is not more than 45 minutes to 1 hour. The water main and the water meter or other convenient connection point within the house.

Contact